If the 95% lower confidence bound is greater than 1.33, they can be extremely confident that their process is capable, even when taking into account the variability from random sampling that affects the estimate.Given: Engineering Specifications = 60 ± 5 USL = 65, LSL = 55 To further assess this estimate, they display a 95% lower confidence bound for Ppk. Using capability analysis, they obtain a Ppk estimate of 1.46, which suggests that the process is capable.

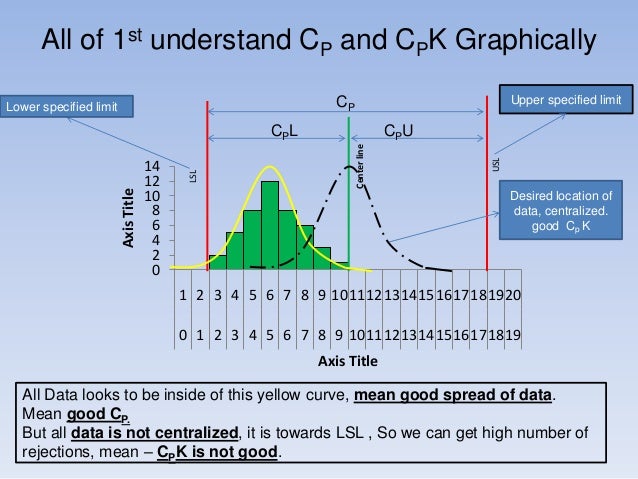

When possible, compare the confidence bounds with a benchmark value that is based on process knowledge or industry standards.įor example, a company uses a minimum benchmark value of 1.33 for Ppk to define a capable process. The confidence interval helps you to assess the practical significance of your sample estimate. That is, if you collect 100 random samples from your process, you can expect approximately 95 of the samples to produce intervals that contain the actual value of the capability index. Instead, you can use a confidence interval to determine a range of likely values for the capability index.Īt a 95% confidence level, you can be 95% confident that the actual value of the capability index is contained within the confidence interval. To calculate the actual value of the capability index for your process, you would need to analyze data for all the items that the process produces, which is not feasible. If the process is centered on target, the Ppk and Cpm values are approximately equal.īecause samples of data are random, different samples collected from your process are unlikely to yield identical estimates of a capability index. If Cpm is lower than your benchmark, consider ways to improve your process, such as reducing its variation or shifting its location.Ĭompare Ppk and Cpm. Many industries use a benchmark value of 1.33. You can compare Cpm to other values to get more information about the capability of your process.Ĭompare Cpm with a benchmark value to assess the overall capability of your process. In this example, the process is on target, but all of the data do not fall within the specification limits. In this example, the data fall inside of the specification limits, but the process is off target. In this example, the data are on target and fall within the specification limits. Lower values indicate that your process may need improvement. Generally, higher Cpm values indicate that your process is more capable. Overall capability indicates the actual performance of your process that your customer experiences over time.

Use Cpm to evaluate the overall capability of your process relative to both the specification spread and the target.

0 kommentar(er)

0 kommentar(er)